Application Tips

Thermoelectric cooler (TEC) is a semiconductor device which is characterized by unique heat pump performance with high efficiency, compactness and durability. The unique ability of TECs to heat and cool, permits them to lower temperature of an object below ambient as well as to stabilize temperature of objects in widely varying ambient conditions.

Here we mention some application tips that can help in optimal use of TECs.

Mounting

Power Supply

Environment

Handling

Heat Dissipation

Reference Data

Brief Summary

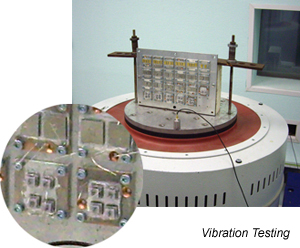

VIBRATIONS AND SHOCKS

-

-

Vibration and shocks are usual for most of devices where TECs are installed, particularly portable field applications, military and airspace programs. Thermoelectric modules have high durability to such dynamic loads. They have been successfully subjected to shock and vibration requirements for aircraft, spaceship, shipboard use and most other such applications many times.

To confirm high durability TECs are exposed to mechanical testing in qualification programs.

Standard mechanical testing is specified in Telcordia GR-468 CORE ((Reliability Assurance for Optoelectronic Devices).

Regular TECs must withstand the minimal following vibration and shock loads:

- Vibration in a range 20 to 2000 Hz with peak acceleration of 20 g

- Single impact - 1500 g level shock in all three axis.

Note: During such mechanical testing a dummy mass imitating a cold object is to be mounted on top of TECs. For most of applications the mass is about 1-2 gram.

Important remark

Above mentioned mechanical durability is related to TEC construction. In real applications different object could be mounted onto TEC cold side. Parameters (size and weight) of cold object mounted in real application to TEC cold side will limit considerably the durability to mechanical loads.

For applications with huge mass of cold objects or probability or high mechanical loads particular testing must be applied to such construction to confirm common durability.