Application Tips

Thermoelectric cooler (TEC) is a semiconductor device which is characterized by unique heat pump performance with high efficiency, compactness and durability. The unique ability of TECs to heat and cool, permits them to lower temperature of an object below ambient as well as to stabilize temperature of objects in widely varying ambient conditions.

Here we mention some application tips that can help in optimal use of TECs.

Mounting

Power Supply

Environment

Handling

Heat Dissipation

Reference Data

Brief Summary

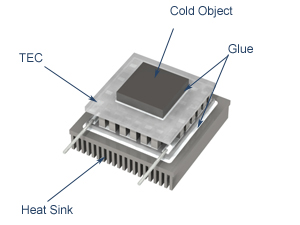

MOUNTING BY GLUING

-

-

The TEC is glued by thermal conductive glue (usually epoxy based compound filled with conductive powder) to header/heat sink, and a cooled object is glued by a similar way on the cold side of the TE module.

The thermal contact and mechanical durability are provided by gluing.

Application

The method application is similar to that of soldering: it is mostly applied to single- and multistage micromodules.

The application for powerful modules is limited due to possible mechanical strains due to thermal expansion.

Advantages

Unlike the mechanical installation it does not demand any additional elements occupying the area. In contrast to the soldering method it does not demand any intensive heating of the mounted surfaces, accurate control of temperatures and a special equipment for high temperature.

Restrictions

Disassembly of mount is complicated or impossible. Usually it is not recommended to heat it up above 150-160°C. Vacuum applications are restricted because of outgassing. Epoxy is sensitive for some chemicals - solvents.

Procedure

- Clean and prepare mounting surfaces on both the TEC and heat sink using methanol, acetone, or general-use solvent. Clean and degrease the module and mounting surfaces to insure that all burrs, oil, dirt, etc., have been removed. Follow the epoxy manufacturer's recommendations regarding proper surface preparation.

- Coat the hot side of the module with a thin layer of the thermally conductive epoxy and place the module, hot side down, on the heat sink in the desired location. Gently push down the module and apply a back and forth turning motion to squeeze out excess epoxy. Continue the combined downward pressure and turning motion until a slight resistance is detected.

- Weight load or clamp the module in position until the epoxy has properly cured. Follow the instructions on the package of thermally conductive Epoxy carefully for specific curing information. If an oven cure is specified, be sure that the maximum operating temperature of the TE module is not exceeded during the heating procedure.

- If the same gluing is needed to mount cold object it could be done with repeating of the same as above procedure as for TEC gluing to heat sink. Or both steps could be done simultaneously: gluing of TEC to heat sink and cold object on top of TEC.