MD10 Series

-

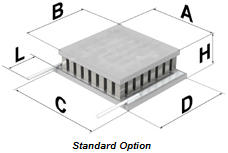

The MD10 Series is the expansion for standard MC10 Series TECs. MD10 Series consist of single-stage thermoelectric coolers based on high-density pellets placement. Most of MD10 single-stage TECs are the analogs of standard MC10 TECs by dimensions, but have the increased cooling capacity. RMT High-density pellets placement technology allows to place more BiTe posts on the same size as regular TECs have. More internal elements means higher cooling capacity, which is up to 60% higher with MD10 Series TECs comparing with regular types. Al2O3 ceramics is applied by default, AlN ceramics is available as an option.

All MD10 thermoelectric coolers are RoHS compliant and qualified by Telcordia GR-468 standard.

MD10 TECs were developed by RMT additionally to general thermoelectric coolers series. MD10 thermoelectric coolers can be used in applications with high heatload and provide higher dT, where regular types may have less efficiency. RMT MD10 TECs are common solution for applications with HHL and BTF packages form-factor.

|

|

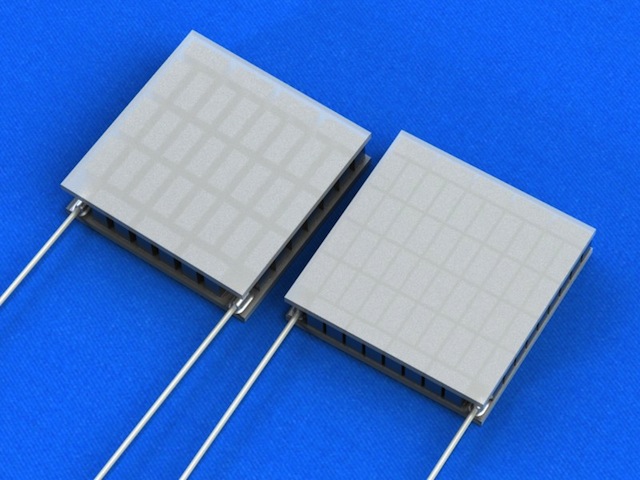

| Fig 1 - Standard 15x15mm2 TEC from MC10 (left)

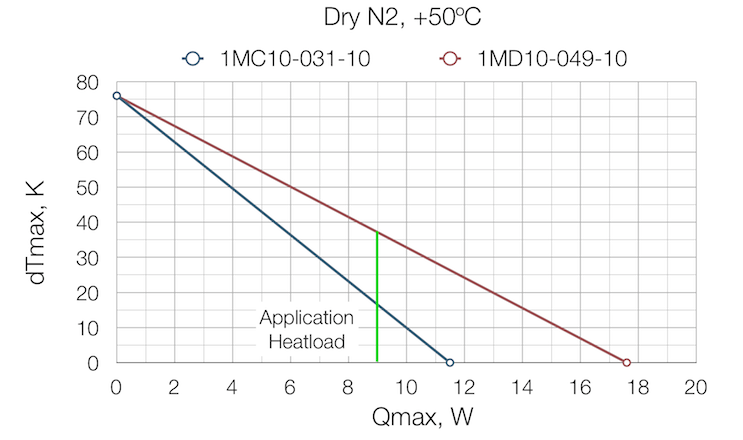

and it’s analog from MD10 Series with 65% higher Qmax | Fig 2 - The difference in performance parameters

between MC10 and MD10 TECs (click to zoom) |

|

Thermoelectric coolers MD10 Series

| |||

|

Performance table at 27C, vacuum.

|

Performance table at 50C, N2.

| ||

Specifications

Important Note: MD10 Series TECs can be manufactured on standard 0.5mm and thick 1.0mm ceramics. This adds an additional flexibility to performance and height optimization in a particular application. It is also possible to combine various ceramics thicknesses to achieve the most optimal results for TEC height.

Please, use On-Line Assistant to find the most optimal thermoelectric cooler by dimensions and performance parameters. The detailed analysis of TEC performance and power consumption can be made with free TECCad software for Windows or special iTECPad app for iPad (available free on App Store).

Options

Information furnished by RMT Ltd is believed to be reliable. However no responsibility is assumed for possible inaccuracies or omission. Specifications are subject to change whithout notice.