Print version

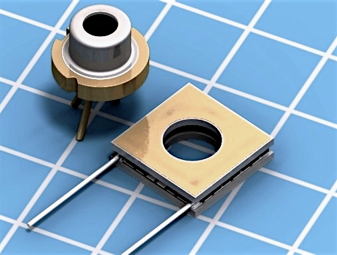

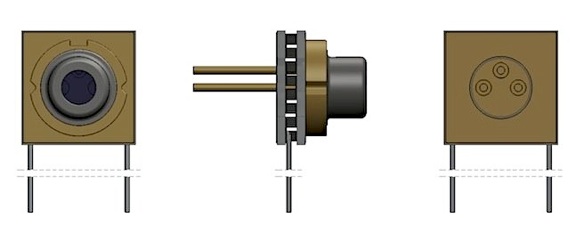

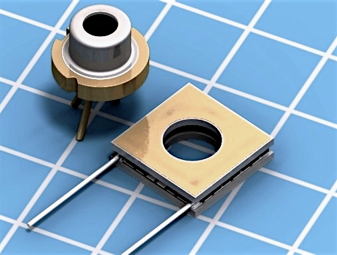

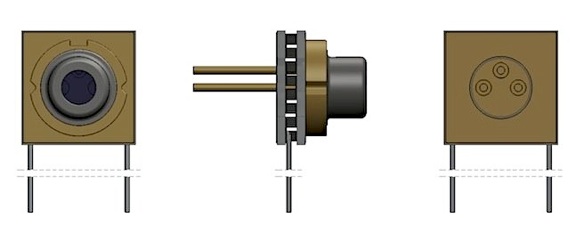

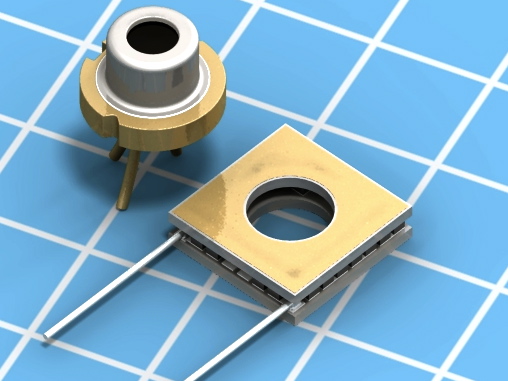

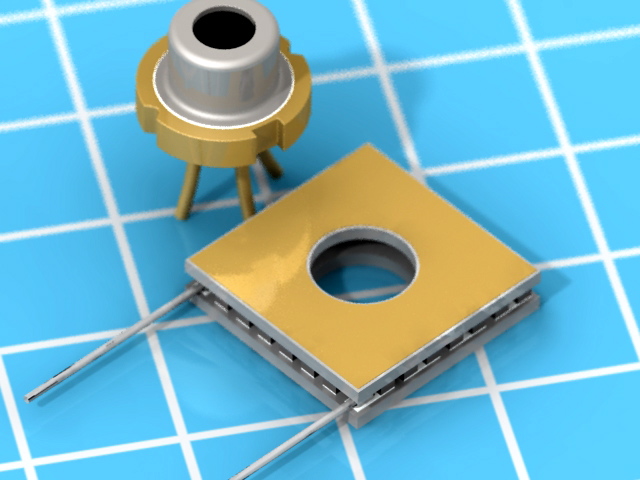

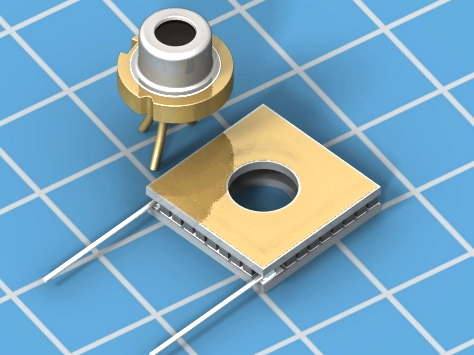

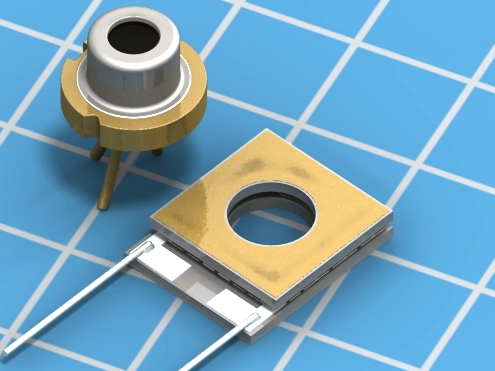

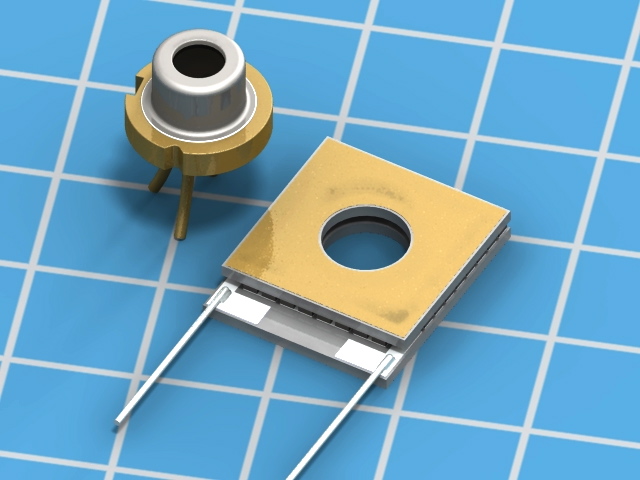

Fig.2 - 1MD06-015-05H (6.6x6.6mm) with TO-56 LD mounted on top

Different ceramics surface options can be applied - blank ceramics, Au plated or metallized and pre-tinned ceramics. Additionally to the standard thermoelectric cooler height there is an option with thin ceramics, that allows to make low-profile thermoelectric coolers in case of height limits. The min available height is 0.9mm.

New center-hole thermoelectric coolers are cost-effective solution for additional performance and stability improvements with standard laser diodes applications on TO-56 or TO-9 header. New thermoelectric coolers are available in a standard product now with trial and volume manufacturing.

Back to Company News

Cool Aperture - new center-hole thermoelectric coolers

Jun 8, 2011

RMT Ltd introduce new types of center-hole thermoelectric coolers, optimized for LD applications with TO-56 or 9mm industrial standard headers. New thermoelectric coolers with dimensions of 6.6x6.6mm and 8.0x8.0mm have five different height and performance options each. Additional high-performance versions are available.

TO-56 and 9mm headers are industry standard and common for laser applications. The 9MM header is a sealed package, usually applied for devices with up to 2W output power. This is a industrial standard low cost package for mid power applications where internal cooling is not required. 9mm header is optimal for high volume applications.

The TO-56 (5.6 mm) header is a hermetically sealed steel type, suitable low power applications (usually up to 150mW max) single mode devices.

Both types are designed for LD applications without active temperature stabilization. Complex assemblies that require strict temperature stabilization (EML TOSA for example), usually are assembled in packages like “Butterfly” or box-type MSA TOSA. In the same time standard un-cooled solutions on TO-56 and 9mm headers may obtain additional advantages and performance in terms of wavelength stability or increased LD output power if to use the active cooling with thermoelectric coolers. And here there are two basic solutions: integrated cooling and outside cooling.

The TO-56 (5.6 mm) header is a hermetically sealed steel type, suitable low power applications (usually up to 150mW max) single mode devices.

Both types are designed for LD applications without active temperature stabilization. Complex assemblies that require strict temperature stabilization (EML TOSA for example), usually are assembled in packages like “Butterfly” or box-type MSA TOSA. In the same time standard un-cooled solutions on TO-56 and 9mm headers may obtain additional advantages and performance in terms of wavelength stability or increased LD output power if to use the active cooling with thermoelectric coolers. And here there are two basic solutions: integrated cooling and outside cooling.

| The integrated solution means a thermoelectric cooler installed on a header with direct contact to LD. The limiting aspect here is in thermoelectric cooler size and performance. Standard TO-56 and 9mm headers have a design with a very small space for thermoelectric cooler mounting. There are certain solutions with bulk technology micro-TECs, introduced by RMT and TEC Microsystems before with about 150mW of Qmax and 1x1mm cold side. Such solution is OK for LD with low heatload.

The thin-film TECs, widely advertised recently, could be a solution also. They have very small size with a very large cooling capacity. But there is a very big disadvantage in terms of maximum dT. Thin-film thermoelectric coolers have twice less dTmax value, comparing with bulk technology types. |

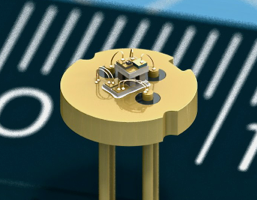

|  Fig.1 - 1MD03-002-xx on standard TO-56 with VCSEL |

The second limiting factor is a number of pins. With standard 3 pins it is not enough to connect LD, photodiode, TEC and thermistor at once. Of course, there is always a solution to make a customized header with more space and more pins. It makes sense for special projects with large volumes potential.

But what if we use the standard cost-effective LD in TO-56 or 9mm header and want to improve it’s performance? There is a simple solution - external cooling. The solution is about to mount LD header on thermoelectric cooler. The placement of header pins is solved by making a central hole in thermoelectric coolers to put them through. The solution works for both types of standard headers - TO-56 and 9mm - as they have the same pin layout.

TEC Microsystems GmbH and RMT Ltd introduce new range of thermoelectric coolers with a central hole, optimized for LD applications with TO-56 or 9mm industrial standard headers. New thermoelectric coolers with dimensions of 6.6x6.6mm and 8.0x8.0mm have five different height and performance options each. Additional high-performance versions are available.

But what if we use the standard cost-effective LD in TO-56 or 9mm header and want to improve it’s performance? There is a simple solution - external cooling. The solution is about to mount LD header on thermoelectric cooler. The placement of header pins is solved by making a central hole in thermoelectric coolers to put them through. The solution works for both types of standard headers - TO-56 and 9mm - as they have the same pin layout.

TEC Microsystems GmbH and RMT Ltd introduce new range of thermoelectric coolers with a central hole, optimized for LD applications with TO-56 or 9mm industrial standard headers. New thermoelectric coolers with dimensions of 6.6x6.6mm and 8.0x8.0mm have five different height and performance options each. Additional high-performance versions are available.

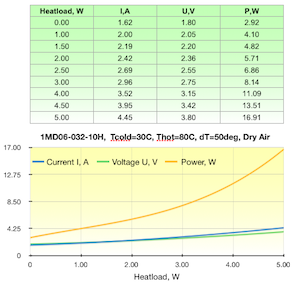

1MD06-032-xxH type is the analog of standard 8x8mm TEC with central hole, but based on HD pellets placement technology, which increases the cooling capacity for TEC.

В

В

Center-hole thermoelectric coolers

| 1MD06 | Type | DTmax K | Qmax

W | Imax

A | Umax

V | AC R

Ohm | H

mm | A

mm | B

mm | C

mm | D

mm | Data Sheet |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1MD06-015-xxH (N=15) | ||||||||||||

| 1MD06-015-05H | 70 | 3,50 | 3,3 | 1,80 | 0,44 | 1,6 | 6,6 | 6,6 | 6,6 | 6,6 | |

| 1MD06-015-08H | 70 | 2,30 | 2,2 | 0,69 | 1,9 | |||||||

| 1MD06-015-10H | 71 | 1,80 | 1,7 | 0,86 | 2,1 | |||||||

| 1MD06-015-12H | 71 | 1,50 | 1,5 | 1,05 | 2,3 | |||||||

| 1MD06-015-15H | 72 | 1,30 | 1,2 | 1,27 | 2,6 | |||||||

| 1MC06-024H-xx (N=24) | ||||||||||||

| 1MC06-024H-05 | 69 | 5,35 | 3,4 | 2,95 | 0,71 | 1,6 | 8,0 | 8 | 8 | 8 | |

| 1MC06-024H-08 | 70 | 3,55 | 2,2 | 1,10 | 1,9 | |||||||

| 1MC06-024H-10 | 71 | 2,95 | 1,8 | 1,40 | 2,1 | |||||||

| 1MC06-024H-12 | 71 | 2,40 | 1,5 | 1,65 | 2,3 | |||||||

| 1MC06-024H-15 | 72 | 1,95 | 1,2 | 2,05 | 2,6 | |||||||

| 1MD06-032-xxH (N=32) | ||||||||||||

| 1MD06-032-05H | 70 | 7,20 | 3,30 | 3,90 | 0,93 | 1,6 | 8,0 | 8,0 | 8,0 | 8 | |

| 1MD06-032-08H | 70 | 4,80 | 2,20 | 1,47 | 1,9 | |||||||

| 1MD06-032-10H | 71 | 3,90 | 1,70 | 1,83 | 2,1 | |||||||

| 1MD06-032-12H | 71 | 3,30 | 1,50 | 2,18 | 2,3 | |||||||

| 1MD06-032-15H | 72 | 2,60 | 1,20 | 2,70 | 2,6 | |||||||

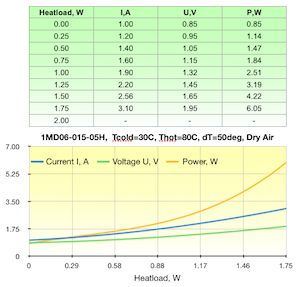

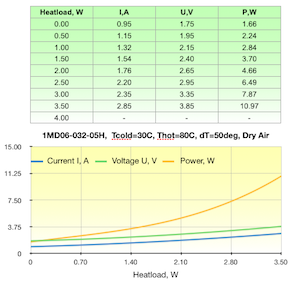

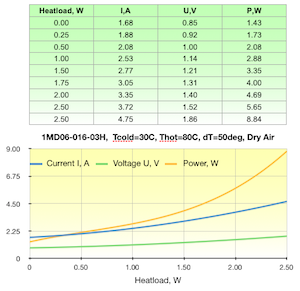

Each thermoelectric cooler has five different height and performance options. Here are some examples of TEC power consumption at typical LD application conditions. Click on the chart to zoom:

Fig.3 - 1MD06-015-05H performance curves |

Fig.4 - 1MD06-032-05H performance curves |

Additionally, there are two modified versions of these new thermoelectric coolers - 1MD06-015-03H and 1MD06-032-03H. They are assembled by HD technology with and modified to increase cooling capacity to 60% higher. It allows to pump about 17W/cm2, that is enough for high-power LD in 9mm header.

Center-hole thermoelectric coolers with the increased Qmax value

| 1MD06 | Type | DTmax K | Qmax

W | Imax

A | Umax

V | AC R

Ohm | H

mm | A

mm | B

mm | C

mm | D

mm | Data Sheet |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1MD06-015-03H (N=15) | ||||||||||||

| 1MD06-015-03H | 68 | 5,50 | 5,0 | 1,80 | 0,27 | 1,4 | 6,6 | 6,6 | 8 | 6,6 | |

| 1MD06-032-03H (N=32) | ||||||||||||

| 1MD06-032-03H | 68 | 11,00 | 5,0 | 3,90 | 0,58 | 1,4 | 8,0 | 8 | 9,4 | 8 | |

Fig.3 - 1MD06-015-05H performance curves |

Fig.4 - 1MD06-032-05H performance curves |

Different ceramics surface options can be applied - blank ceramics, Au plated or metallized and pre-tinned ceramics. Additionally to the standard thermoelectric cooler height there is an option with thin ceramics, that allows to make low-profile thermoelectric coolers in case of height limits. The min available height is 0.9mm.

New center-hole thermoelectric coolers are cost-effective solution for additional performance and stability improvements with standard laser diodes applications on TO-56 or TO-9 header. New thermoelectric coolers are available in a standard product now with trial and volume manufacturing.