Out of pyramids - new 3-stage thermoelectric cooler types

Jun 16, 2010

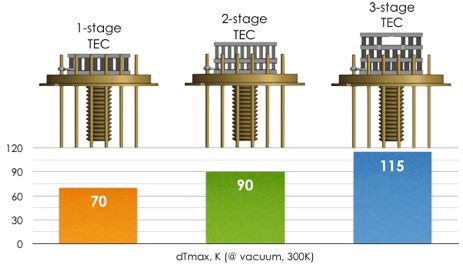

Multi-stage thermoelectric coolers are required mainly for IR and X-Ray detector applications. Lower operating temperatures provides better sensitivity and reduce noise. Single-stage coolers with max 70-73 degrees of dT (at room conditions) are less required now. Developers and manufacturers are switching for 2- and 3-stage thermoelectric coolers to get deeper cooling level. They need also enough space on the cold side for detector. And it is required to be a compact low power consumption solution, especially for hand-held devices. But for the standard 3-stage coolers with pyramidal shape this is hard to fit all these requirements at once.

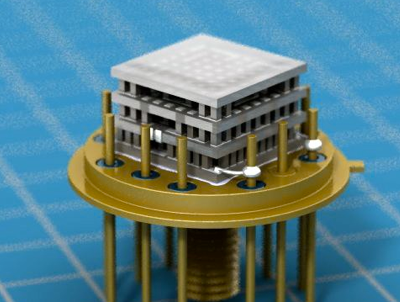

Standard multi-stage TECs have pyramidal shape. Each previous stage has to be larger than next one by cooing capacity. It has to pump the heat from the next stage and add additional cooling performance. In most cases it is realized by different numbers of BiTe elements per stage. Briefly, every previous stage has more elements than next one. The pyramidal form is classical and standard for many TE coolers manufacturers. But the pyramidal TEC is not optimal. For example, in case of 4x4mm cold ceramics size, the bottom ceramics is usually about 12x12mm - nine times bigger(!). If customer needs 8x8mm cold side, the dimensions of hot side are out of 20x20mm and so on. TE cooler finally is much bigger than sensitive elements of detector themselves.

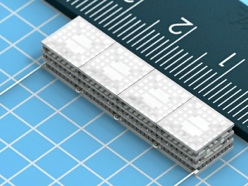

New 3MDC TECs have the the same size of top and bottom ceramics. New TECs are assembled with standard and HD pellets placement technology to reduce the size of bottom stages and increase cold ceramics area on the top.

Fig.1 - New 3MDC TECs in comparison with regular typesВ |

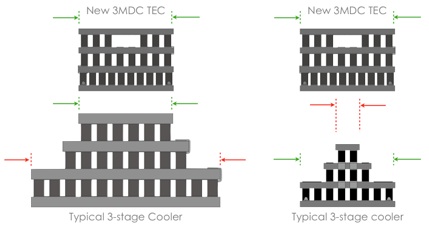

Fig.2 - New 3MDC TEC on standard TO-8 |

For instance, standard packaging solution with TO-8 (or TO-66) header is quite typical for many detector types. Usually single-stage or 2-stage TE cooler is applied there in case of large detector size. In case of typical 3-stage cooler on TO-8 header the size of cold ceramics is max 4x4mm.

For instance, standard packaging solution with TO-8 (or TO-66) header is quite typical for many detector types. Usually single-stage or 2-stage TE cooler is applied there in case of large detector size. In case of typical 3-stage cooler on TO-8 header the size of cold ceramics is max 4x4mm.

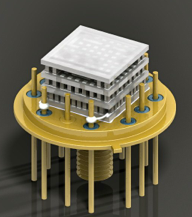

With new 3MDC TECs 3-stage cooler on standard TO-8 header has 8x8mm cold ceramics.В В Quad shape of 3MDC coolers also suitable for connecting TECs in stack to get more space for sensing arrays - the expandable and flexible way to provide 3-stage cooling level almost for any required detector size.

Each of new 3MDC coolers has five different height/performance options for optimal fit in application. Various ceramics surface options are available (blank or metallized). Customized Au patterns on the cold side are available by request.

TEC Microsystems provides new 3MDC TE coolers separately or assembled on standard headers. Mounting on the customer headers is provided also.

With new 3MDC thermoelectric coolers TEC Microsystems continues to to provide high performance multi-stage thermoelectric cooling solutions for detector applications.

Fig.4 - Three solutions with the same cold ceramics size, provided by TEC Microsystems and RMT

spec