Thermoelectric Coolers with Holes - big update

Jul 21, 2015

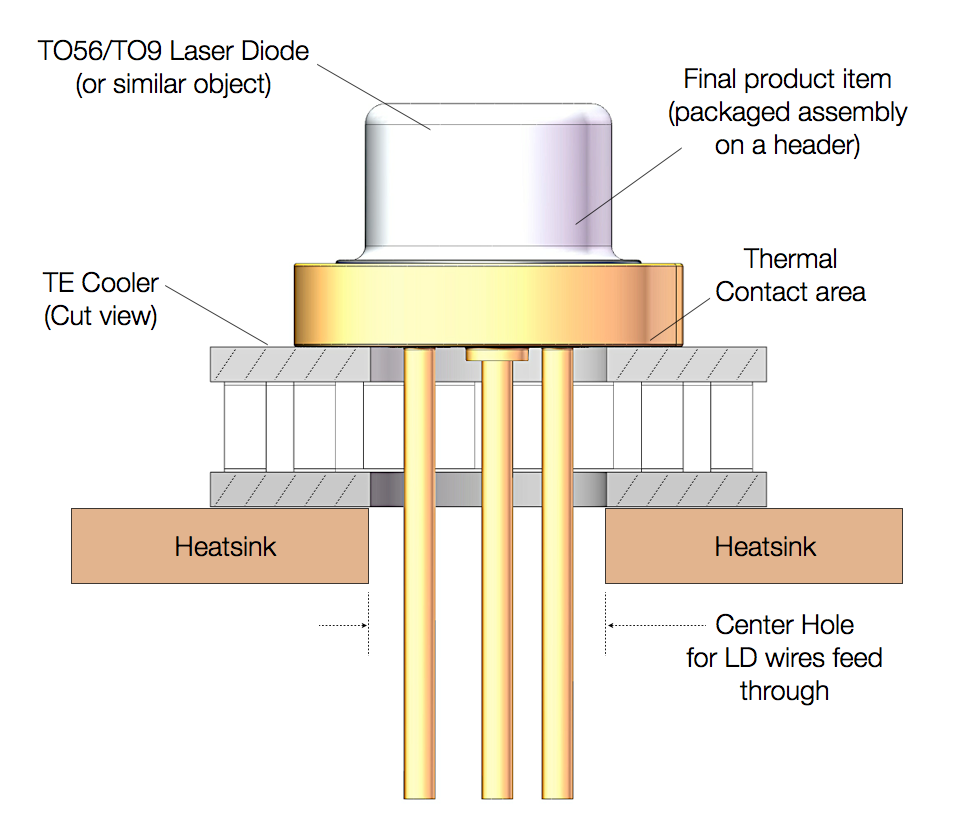

RMT Ltd introduce more than 20 new thermoelectric coolers with holes for "external cooling". Term "external cooling" means TEC attached to the entire assembly on a header, rather than to a heat-generating object. There are two typical cases where thermoelectric coolers with holes can be used: 1) powerful LD on TO-38/46/56/9 type headers with not enough space to mount TEC on a header, 2) already sealed (un-cooled) devices, where the advanced temperature stabilization gives extra benefits in terms of laser wavelength stability, optical power output, device lifetime or sensitivity.

|  |

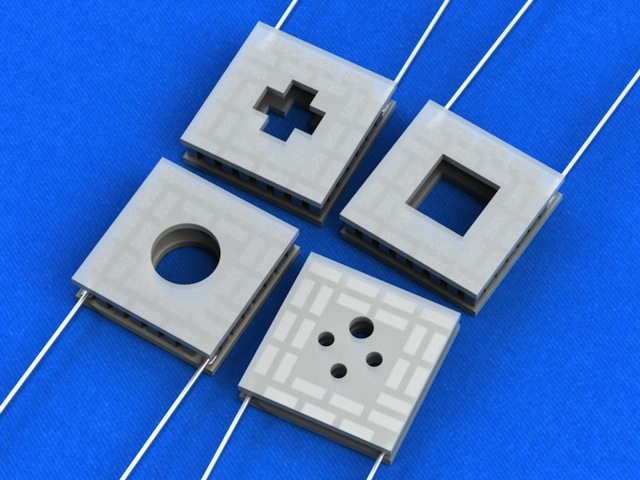

| Fig 2 - Flexibility with

holes modifications | |

| |

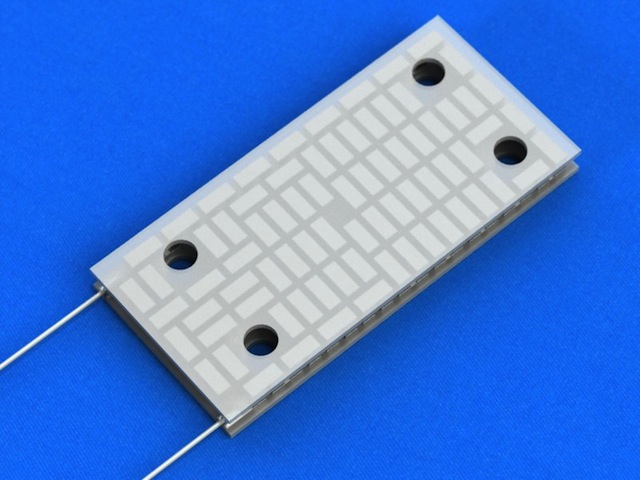

| Fig 1 - External and internal cooling methods (click to zoom) | Fig 3 - Customized TEC for external

cooing of regular 14-pin “Butterfly” LD package |

In case of "external" cooling the entire sealed assembly on a header is being mounted on TEC with a hole to put the pins through. The TEC then is installed on an appropriate heatsink. The “external” cooling is a good solution to implement advanced temperature stabilization in applications with already sealed and un-cooled devices.

Thermoelectric coolers with holes are also ideal for various laboratory testing equipment, LD calibration tools, optoelectronics setup instruments, devices quality control and environmental testing, reliability testing and similar applications. RMT provide the complete flexibility with holes modification, layout customization and development of special thermoelectric coolers with holes for specific applications. The updated list of available solutions is available byВ this link.

Back to Company News